PBT Works

PBT Works is a Czech manufacturer of advanced PCB, stencil, and maintenance cleaning machines for the electronics manufacturing industry, boasting over 30 years of experience and more than 4,000 installations worldwide.

Cleaning machines

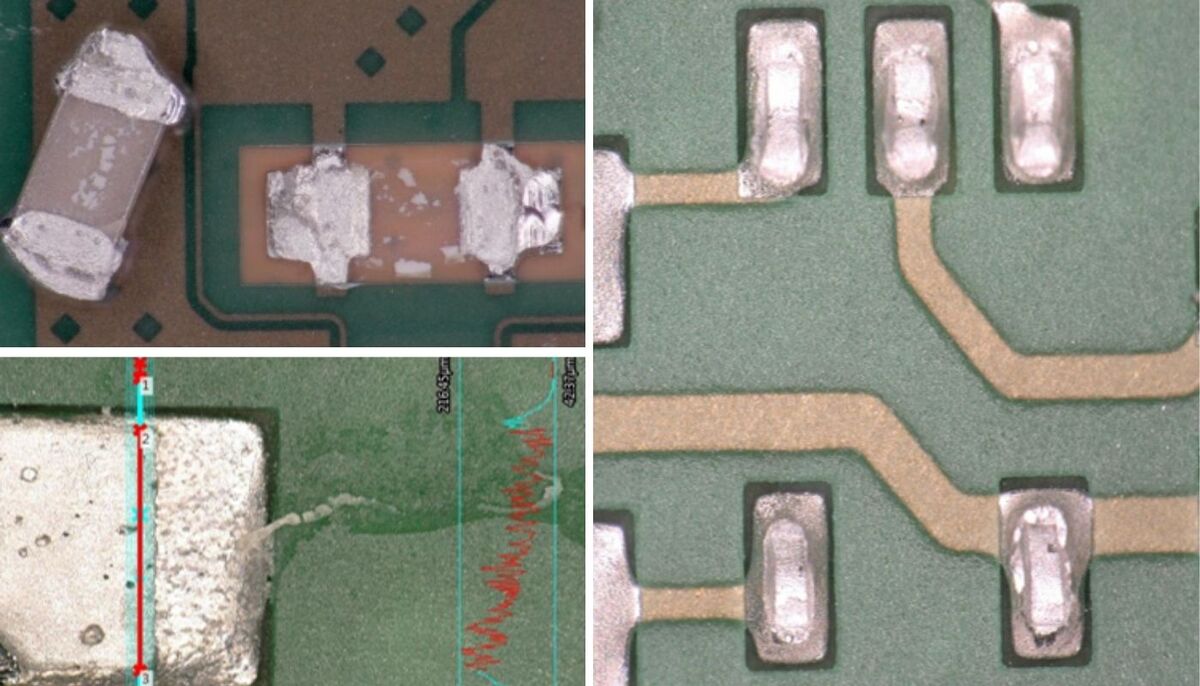

Precision Cleaning Technology for Modern Electronics Manufacturing

PCbA cleaning

Professional PCB Cleaning Solutions

PBT Works designs automatic spray-in-air closed-loop cleaning machines that significantly improve electronics reliability through controlled post-soldering cleaning.

PBT systems handle any PCB size or complexity, with flexible tooling that adapts from low-volume to high-capacity production.

stencil cleaning

Professional stencil cleaning – eliminate manual process risks

PBT Works automated stencil cleaning systems ensure complete residue removal of solder paste and adhesives, delivering consistently clean stencils that maintain print quality and reduce production costs. The result: reliable printing performance, minimized defects, and optimized throughput in your SMT line.

Maintenance cleaning

For better longevity of filters, pallets and magazines

Cleaning of soldering pallets and jigs improves the PCBA placement precision for the solder wave or selective soldering machine, reduces cross-contamination by flux and significantly prolongs the lifetime of the pallets.

Regular cleaning of condensation traps and filters from SMT ovens maintains their heat transfer functionality, leading to a reliable soldering process.

mechanical cleaning

Precision mechanical parts washing

PBT Works systems deliver precise parts washing that meets the latest technical cleanliness requirements, ensuring optimal component functionality while improving corrosion resistance and coating adhesion.

With complete process control, documentation, and MES connectivity, their machines provide full traceability for your quality requirements.

Cleaning diagnostics

Cleaning process development

Building an effective cleaning process requires to test and measure. Electronic assembly cleaning technology is a complex process. Several factors must be managed to achieve acceptable results for ionic, organic, and particle cleanliness.

Over our nearly 30-year tradition in cleaning, PBT has received valuable insights into the challenges caused by improper component or component configuration design. We can share this information with you and help you save time, materials, and money to address the consequences of bad design.

The most frequent task of PCBA cleaning is defluxing. The optimal choice of solder material (paste, liquid flux, and wire) should be made together with testing for soldering and printing. Not every material which is optimal for soldering may also be optimal for cleaning.

PBT can help you characterize soldering material and compare your candidates for the best suitable cleaner. PBT have a comprehensive library of different solder paste cleanability values, measured by unique automatic technology.

SMT screen printers

Manual and semi-automatic printers

PBT is a producer of SMT stencil printers for prototyping as well as small to medium-sized production.

The main focus is on table tops, suitable for laboratories, universities, R&Ds, start-ups, and small production lines.

About PBT Works

PBT Works ranks among the world’s leading manufacturers of cleaning technology for electronic assembly and tooling. Based in the Czech Republic, their family-owned company has developed and manufactured cleaning machines since 1992, accumulating over 30 years of practical experience in electronics cleaning processes.

Their product portfolio centres on automatic spray-in-air closed-loop zero-drain cleaning machines designed for PCB assemblies, SMD stencils, squeegees, soldering pallets, and industrial components. The company’s flagship systems include the award-winning HyperSWASH for high-end PCBA cleaning and the SuperSWASH series for high-volume stencil and maintenance cleaning applications. These machines utilise direct spray technology with linear motion systems, ensuring consistent cleaning results across complex electronic assemblies.

PBT Works serves critical industries including medical devices, automotive electronics, and aerospace applications where component reliability is paramount. Their cleaning systems remove flux residues, solder paste, organic contaminants, and particles from electronic assemblies with thickness capabilities down to 25-50 microns for fine-pitch stencils.

The company maintains its own manufacturing facilities and applies advanced computing and simulation methods in machine design.

Their systems feature MES connectivity, real-time concentration monitoring, and comprehensive process documentation capabilities. With over 4,000 installations worldwide, PBT Works has established partnerships with multinational corporations that require precise contamination removal and surface preparation.

Additionally, PBT Works manufactures off-line solder paste printers for SMT applications, focusing on table-top solutions suitable for laboratories, R&D facilities, and small production environments.

Tim-Nordic has been a PBT partner since 2015—count on our experience.