MODI & DiVis

MODI and its daughter company DiVis deliver comprehensive material and production monitoring solutions with 100% traceability for incoming and outgoing goods handling across manufacturing operations.

Optimise your MATERIAL processes

Faster incoming goods reporting, detailed traceability and reliable outgoing goods documentation. They way you want it.

Incoming goods SCANNER 5.0

100% component traceablity faster

MODI WES 5 captures and validates all incoming shipments, from SMD reels to pallets to ensure complete traceability from the moment goods enter your warehouse.

PACKTRACE

Faster and traceable box packing

Packtrace keeps track of the products you pack in the box. Integrate with ERP and WMS systems.

Collect shipping data for better decision-making.

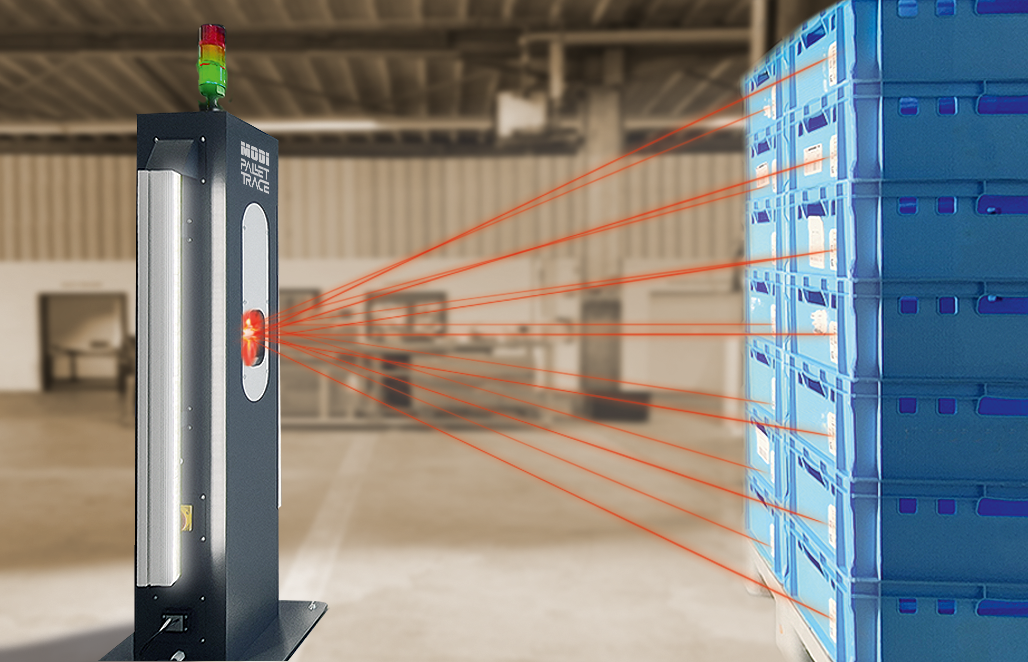

PALLET TRACE

Scan palleted goods with one single scan.

Comprehensive hardware and software solutions to support traceability of pallets at every step of the warehouse process. Large scanning area of up to 220 cm in height and 120 cm in width.

SOFTWARE

Customised software, developed In-House

With 30+ years of expertise and 100% in-house development, we deliver tailored solutions that integrate perfectly with your existing processes, software and equipment.

About MODI

MODI specialises in comprehensive material and production monitoring systems that deliver complete traceability throughout manufacturing operations with a focus on the electronics manufacturing industry. Their solutions focus on precise tracking of incoming and outgoing goods handling, ensuring full visibility across the entire production chain.

The company’s monitoring systems provide manufacturers with real-time oversight of material flow, from raw material receipt through final product shipment. MODI’s technology enables 100% traceability, allowing organisations to track every component and finished product through each stage of the manufacturing process. This level of monitoring supports quality control initiatives, regulatory compliance requirements, and supply chain optimisation efforts.

MODI’s solutions integrate seamlessly with existing manufacturing systems, providing detailed documentation and reporting capabilities that meet industry standards. Their monitoring technology captures critical data points, including material specifications, batch information, processing parameters, and quality metrics. This comprehensive data collection supports both operational decision-making and regulatory reporting requirements.

The company serves manufacturers across various industries who require precise material tracking and production monitoring capabilities. MODI’s systems are particularly valuable for organisations operating under strict quality standards or regulatory frameworks that demand complete traceability documentation.

Their technology platform supports both incoming goods verification and outgoing product certification, ensuring that all materials and finished products meet specified requirements. MODI’s monitoring solutions help manufacturers maintain consistent quality standards while providing the documentation necessary for compliance audits and customer requirements.

DiVis Trace GmbH is a reliable partner for traceability, logistics, and production monitoring. With integrated hardware and software solutions, DiVis optimises business processes and ensures seamless integration into ERP and other system environments.

In close partnership with MODI, DiVis combines innovation with years of experience to deliver customised solutions.

Solution Areas:

- Goods Dispatch: Intelligent packing and pallet scanning solutions for error-free, fully documented shipping.

- Goods Receipt: Comprehensive capture and management of electronic components for complete traceability.

- Storage: Efficient, flexible systems ensuring maximum transparency.

- Production: Barcode-based traceability, MES integration, process control, and cost reduction.